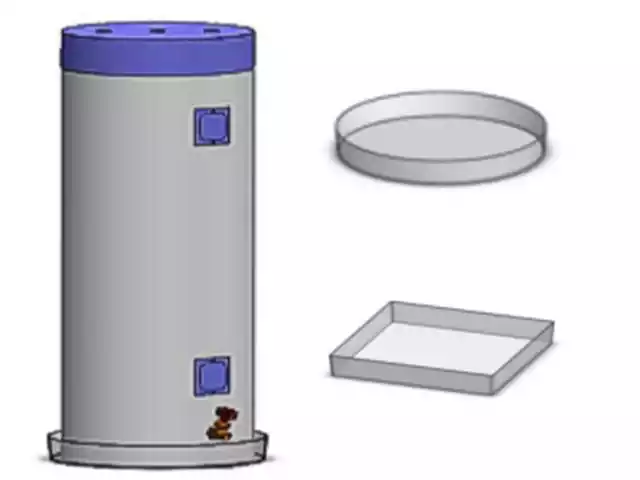

Roto Mold Tank

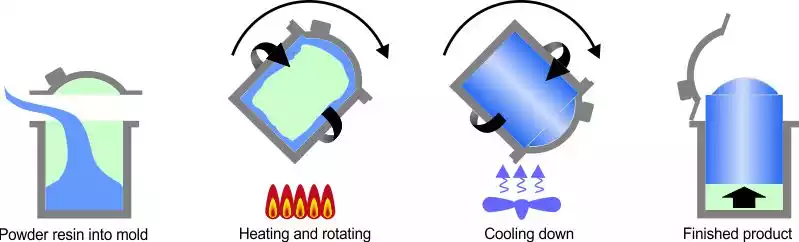

Rotational Molding

Looking for a custom tank solution? Our rotationally molded (roto mold) tanks are a durable, cost-effective option for commercial, agricultural, and industrial applications. The roto molding process creates seamless, one-piece tanks that are corrosion-resistant, chemical-resistant, and watertight; it's perfect for long-term liquid or chemical storage.

Customize your tank with a wide range of designs, textures, and surface finishes to match your specific needs. Contact our team to find the right custom roto mold tank for your next project.

What is Rotational Molding

Rotational molding (or roto molding) is a smart, cost-effective way to create strong, seamless plastic tanks. It works by heating polyethylene resin inside a rotating mold, which evenly coats the interior to form watertight, consistent walls. This process produces tanks that are durable, corrosion-resistant, and built to handle tough conditions like vibration during transport. Additionally, roto molding is faster and more affordable than traditional methods—giving you long-lasting storage without the high cost.

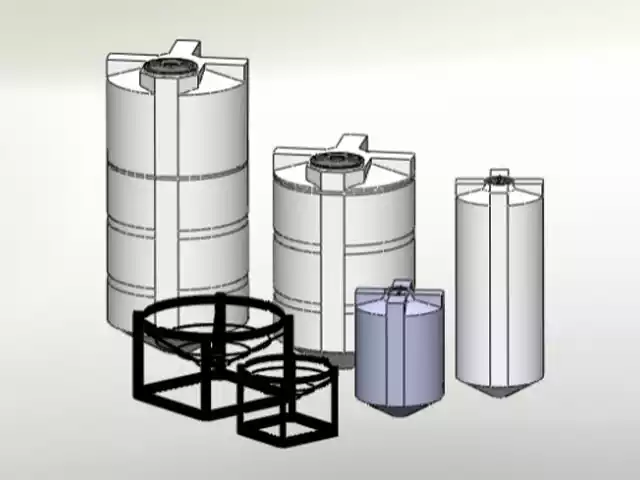

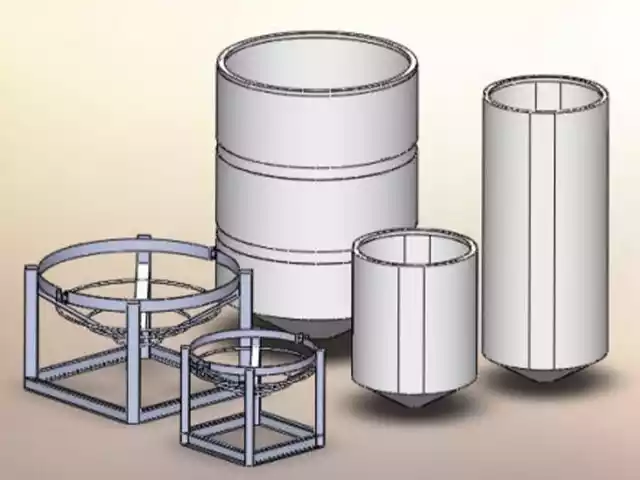

Roto Molding Tanks

Roto molding is a perfect manufacturing technique if you need to customize your tank. The thermoplastic process gives you unlimited options for water and chemical storage, diesel fuel storage, industrial storage, agriculture water storage, and more. Roto molded tanks are lightweight and easy to transport, are rust and corrosion resistant, and give you endless possibilities for tank size, shape and design.

Industrial Tanks

|

|

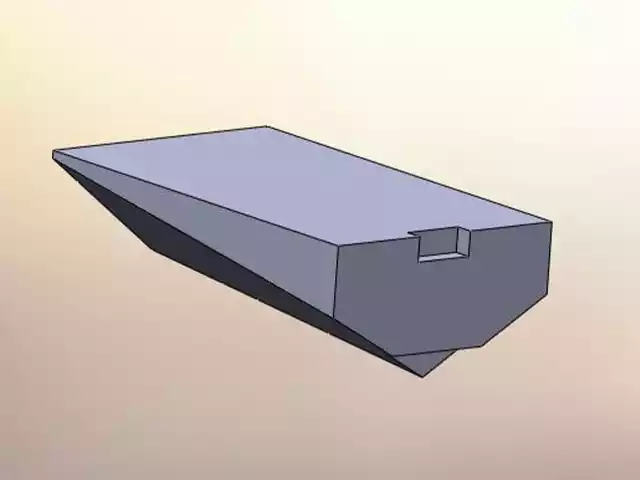

Marine & Boat Tanks

|

|

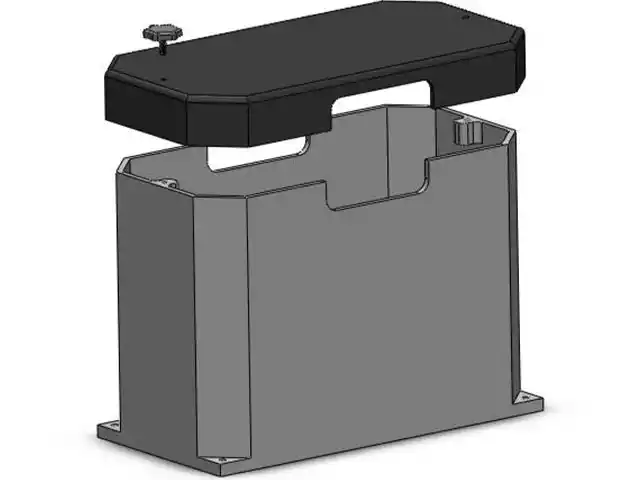

Marine Battery Boxes

|

|

Agricultural Tanks

|

|

Refuse Containers |

|

Recreational Vehicle Tanks

|

|

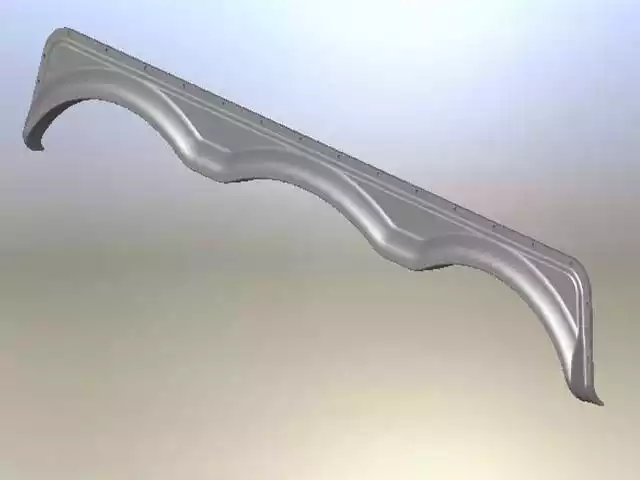

Recreational Vehicle Fender Skirts |

|

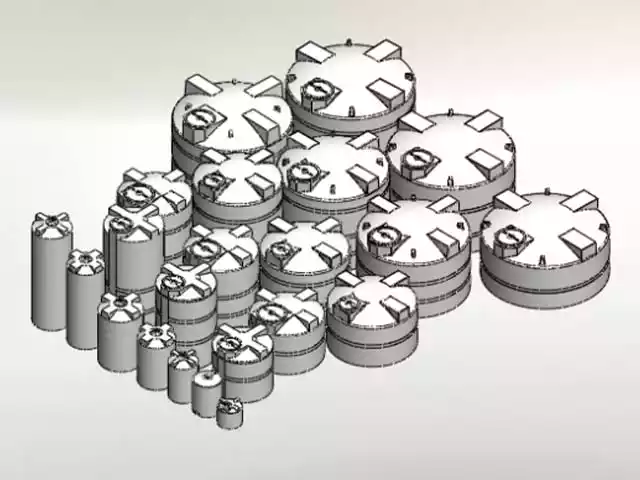

Water Storage Tanks |

|

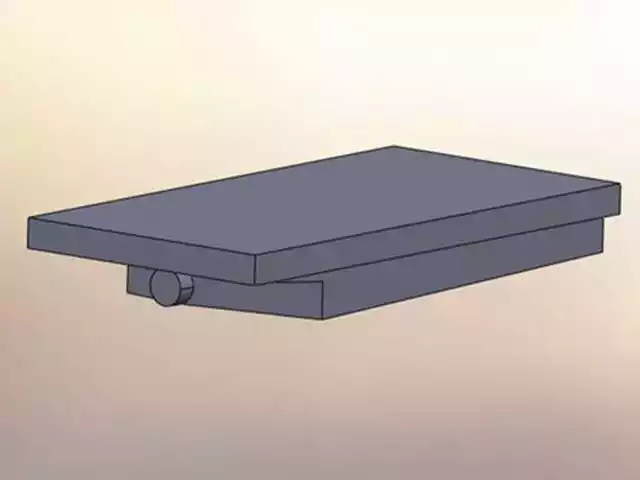

Water Heater Pans

|

|

Our Roto Mold Process

We are dedicated to providing a collaborative and efficient process for your custom roto-molding project. We have a multi-step process giving careful attention to detail and precision.

- We work closely with you to identify your specific tank needs; then create a detailed design prototype.

- Once the design is approved, we build a stainless steel mold to meet all of the requirements outlined during the design process.

- Our mold must meet our high quality standards before we schedule your first tank run with our state-of-the-art rotational molding machines.

- After your tank fabrication is complete, we inspect the tank for any defects or imperfections. Strict quality control measures ensure your tank meets your exact specifications, as well as adhering to our rigorous standards. The result is a high-quality, durable, custom-designed tank that meets your specific project needs. Call us today for more information about our custom roto-molding solutions.

Download

See our Specialty & Custom Tanks (pdf) for more details.

Roto Mold Tank Applications

Roto molding tanks are designed to be sturdy and leak-proof, making them the perfect choice for a wide variety of applications including construction, farms, cities, industry, marine and many other uses. Because tanks meet specifications for water recovery and water treatment, they are often used for water containment, water storage and other liquid storage. We customize tanks and other parts for a wide variety of uses such as portable barriers and cones, carts and carriers, playgrounds, automotives, sporting goods, spill containment, and more. Visit our Marine Holding Tanks page to see more options.

Other applications include:

| Wastewater | Fuel Storage |

| Irrigation | Chemical Processing |

| Rainwater Collection | Emergency Water Storage |

| Composting | Agriculture and Farming |

| Construction Water Storage | Mining and Minerals |

| Fuel Tanks | Recreation | Spill Containment | Automotive industry | Construction Carts and Carriers | Environmental Services | Portable Traffic Barriers | Petroleum and Oil | Marine and Boating | Food and Beverage Industry | Defense and Military | Playground Equipment | Medical and Healthcare | And More… |

Roto Mold Tank Frequently Asked Questions

Rotational molding gives you the opportunity to choose not only the size and shape of your tank, but also intricate or unique details specific to your tank. Because roto mold tanks are seamless, they are also leak-proof and long-lasting. Our roto tanks are also lightweight, durable, and often more cost effective, giving you many options when choosing your tank.

Our roto molded tanks have a wide range of applications. They are strong, rust and corrosion resistent, making them a good choice for multiple industries. Tanks can be used for wastewater chemicals, fuel, compost, beverages and many commercial uses. Talk to one of our tank specialists to find the custom tank for your specific needs.